What is Ready Mix and Redi Mix?

Ready Mix and Redi Mix Concrete: What You Need to Know

In construction management, understanding the distinctions and applications of Ready Mix and Redi Mix concrete is vital for optimizing project workflows, ensuring quality control, and maintaining schedules. Both terms refer to pre-blended concrete delivered directly to the site, but their proper utilization can significantly impact project outcomes. Here’s an in-depth look at these materials and their roles in efficient project execution.

What is Ready Mix Concrete?

- Definition: Ready-mix concrete is produced at a central batching plant, precisely formulated to meet specified mix designs.

- Transport: Delivered in specialized rotary drum trucks that keep the concrete in a plastic, workable state during transit.

- Usage in Construction: Offers consistent quality, making it suitable for large-scale projects where uniformity is critical.

- Advantages:

- Reduces on-site mixing time.

- Ensures concrete properties adhere to project specifications.

- Facilitates better scheduling and resource planning.

What is Redi Mix?

- Origin & Terminology: Redi Mix is often used as a brand name that has become a generic term for pre-mixed, ready-to-pour concrete.

- Application: Supplies pre-mixed concrete to construction sites, emphasizing convenience and quick deployment.

- Industry Usage: Common in regional contexts; essentially synonymous with ready mix, but may refer to a specific supplier.

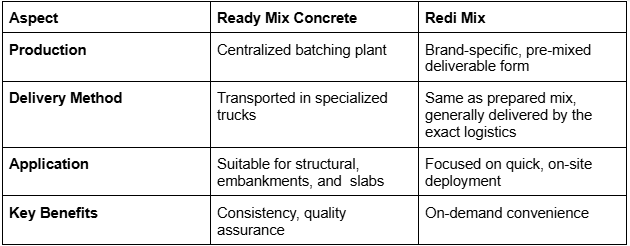

Core Similarities and Differences

Strategic Considerations

Incorporating ready mix or Redi Mix concrete into project planning involves several key considerations to optimize efficiency:

- Material Specifications Alignment

- Match concrete grades to structural requirements—strength, durability, workability.

- Coordinate mix designs with the supplier to ensure compliance with project specs.

- Scheduling & Logistics

- Plan delivery windows to align with pour schedules, minimizing delays.

- Use real-time communication with suppliers to handle potential disruptions.

- Quality Assurance & Control

- Verify supplier certifications and batch records.

- Implement on-site testing (such as slump tests and cylinder breaks) to confirm that the delivered concrete matches the specifications.

- Handling & Pouring Techniques

- Coordinate with pour crews for optimal placement.

- Ensure proper vibration, finishing, and curing protocols are followed to prevent defects.

Risks and Challenges of Improper Management

- Timing & Delivery Delays: Mismatch between delivery schedules and project progress can cause bottlenecks.

- Mix Variability: Deviations in the mix can compromise structural integrity.

- Quality Control Failures: Lack of oversight may lead to non-compliant concrete, risking durability.

- Cost Overruns: Rework due to poor quality or scheduling inefficiencies increases expenses.

- Site Safety: Improper handling or rushing pours may introduce hazards.

Optimizing Usage of Ready Mix and Redi Mix

- Pre-Planning:

- Establish precise pour schedules aligned with project milestones.

- Communicate precise specifications and quality standards with suppliers.

- Supply Chain Management:

- Develop relationships with trusted suppliers to ensure reliability and consistency.

- Incorporate contingency plans for potential delays or batch discrepancies to ensure continuity of operations.

- On-Site Coordination:

- Assign experienced supervisors to oversee delivery, placement, and curing.

- Use testing and inspection to verify concrete quality at delivery.

- Data Logging & Documentation:

- Maintain records of delivery times, batch numbers, and testing outcomes for accountability.

For project managers and construction supervisors, leveraging ready mix or Redi Mix concrete is integral to maintaining project timelines, controlling costs, and ensuring structural quality. Proper planning, supplier coordination, and quality oversight are essential to maximize the benefits of these materials. When managed effectively, ready mix concrete can be a powerful component in delivering successful, durable construction outcomes.

Are You Planning a Job in Need of Ready-Mix Concrete in Southwest Michigan?

If your next job is in

Kalamazoo,

Plainwell,

Benton Harbor, or

South Haven, MI, and it requires

ready-mix or Redi Mix concrete,

contact us at Bos Concrete. We’ve been supplying this area of Michigan with ready-to-pour concrete mix for years. Plus, we have trucks that can pump your ready mix into the tightest spaces.